- Steel Wire Mesh[10]

- Other Hardware[1]

- Filter Meshes[10]

- Barbed Wire[2]

- Iron Wire Mesh[10]

- Copper Wire Mesh[2]

- Other Industrial Filtration Equipment[3]

- Other Wire Mesh[3]

- Filter Cloth[5]

- Door & Window Screens[5]

- Fiberglass Mesh[2]

- Metal Building Materials[3]

- Steel Structures[1]

- Fencing[6]

- Air Filter[1]

- Coffee & Tea Sets[1]

- Water Filter[1]

- Vibrating Screen[1]

- Testing Equipment[2]

- Stainless Steel Pipes[6]

- Steel Pipes[1]

- Contact Person : Mr. Wang Billows

- Company Name : Forward Wire Cloth Import And Export Ltd. Of Wuxi

- Tel : 86-510-82602996

- Fax : 86-510-82793237

- Address : Jiangsu,Wuxi,Room 603, 6th Floor, Golden Phoenix Mansion, Wuxi, Jiangsu Province 214044, China.

- Country/Region : China

- Zip : 214000

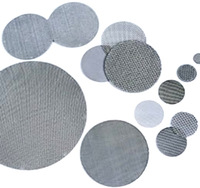

Wire Mesh Disc

Wire Mesh Disc

Metal wire mesh can be processed into different shape, we call it mesh disc..

Wire mesh discs made by stainless steel weaving wire mesh, phosphate copper wire mesh, copper wire mesh etc. can be processed into different shape via punching machine.

Wire mesh disc is widely used in all areas of filtration including liquid, gas, and solid material.

According request by sample or drawing, our company can process the shape like round, square, oval, ring etc.

Discs can contains different layers from single to multi layer after welded.Fineness of disc filters: from 10 mesh to 2800 mesh with plain/twill/dutch weaving mesh.

Diameter of the wire mesh disc screen: from 5mm to 580mm (1/8" to 22")

All process are processed in our own company.

Stainless Steel Wire Mesh Disc

The apparent difference of Reverse Dutch Weaving compared with standard Dutch weave lies in the thicker warp wires and less weft wires. Reverse Dutch woven stainless steel wire cloth offers finer filtration and finds popular application in petroleum, chemical, food, pharmacy and other fields.Through constant technological innovation and improvement, we can produce stainless steel wire mesh of various specification in reverse Dutch weaving patterns.

| Mesh | Wire diameter(μm) | Micron Retention (μm) | Porositytheor.(%) | Weight (kg/m2) | Cloth Thickness (mm) | ||

| Warp | Weft | nominal | absolute | ||||

| 720x140-150 | 35 | 110 | 15 | 16-20 | 52 | 0.65-0.70 | 0.15-0.18 |

| 630x125-130 | 42 | 125 | 17 | 22- 26 | 53 | 0.75-0.85 | 0.20-0.22 |

| 600x100-105 | 42 | 140 | 25 | 34- 38 | 57 | 0.75-0.80 | 0.22-0.23 |

| 280x60-70 | 90 | 200 | 40 | 54- 60 | 56 | 1.34-1.55 | 0.38-0.40 |

| 175x40-50 | 150 | 300 | 60 | 65- 72 | 55 | 2.1-2.40 | 0.57-0.60 |

| 130x30-35 | 200 | 380 | 80 | 95-105 | 57 | 2.7-3.10 | 0.77-0.80 |

| 175x 37 | 85 | 100-106 | 54 | 2.10 | 0.57 | ||

| 170x 40 | 90 | 106-118 | 55 | 2.10 | 0.57 | ||

| 260x 40 | 125 | 112-125 | 62 | 2.25 | 0.62 | ||

| 84x 14 | 450-530 | 62 | 3.50 | 1.15 | |||

Wire Mesh Disc